Find the right propeller

Selecting a boat propeller

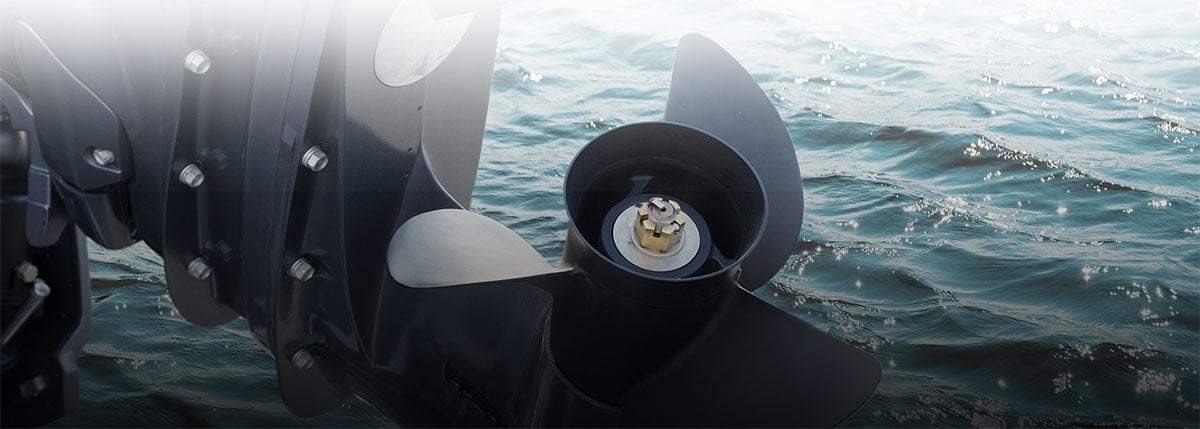

Selecting the right boat propeller is an important factor in maximizing your boat’s performance. Determining the correct size and style of boat prop will keep the engine operating within its recommended RPM range and allow it to apply its maximum horsepower to the water

Materials

We offer propellers made of composite plastic, aluminum, and stainless steel.

Composite boat props offer good performance, are durable, and inexpensive (less than $100). They also offer some protection for your lower unit during a prop strike since the blades are designed to break off the hub with little impact. Unfortunately, this situation would disable the boat. Keeping a spare prop onboard is important so that you aren’t left stranded after prop damage. These propellers are popular with boaters in shallow waters that are more likely to hit something with the prop.

Aluminum props are the most common and are suitable for the widest range of outboard and sterndrive applications. Priced higher than composite props but significantly lower than stainless steel. Aluminum is the best combination of performance and affordability.

Stainless Steel props offer a performance advantage over aluminum due to stiffer, thinner blades and more advanced designs. Best choice at speeds over 50mph, or if your boat is running over oyster beds or sandbars regularly. Stainless costs more but is five times more durable than aluminum. Stainless props can be repaired, at a higher cost, to like-new condition, while repaired aluminum will suffer from metal fatigue and a loss of strength.

Composite

Aluminum

Stainless Steel

Not all props are the same!

Size - Propeller size is described by referring to diameter and pitch. Diameter is twice the distance from the center of the hub to the tip of any blade. Generally smaller diameter props correspond with smaller engines and boats, while larger diameter props correspond with larger boats. Pitch is the forward movement of a boat propeller through one complete revolution measured in inches. Lowering prop pitch will increase acceleration and pulling power. A higher pitch prop will make a boat go faster as long as the engine has enough power to keep the RPMs in the optimum range. If the engine doesn’t produce enough power to run a higher pitch prop all performance suffers and engine damage can result. It’s important to select the prop size that lets your engine operate at WOT within its correct RPM range.

**Wide Open Throttle (WOT) RPM Range** The correct RPM range to achieve optimal WOT is generally between 5000 and 5500 RPM for outboards and 4400 to 4800 for sterndrives, depending on engine type. This information is included in the owner’s manual of a new boat or engine.

Number of Blades - Three or four blades work well in either sterndrive or outboard applications. Three-blade designs give you all-around performance with an advantage on top end speed. Four-blade designs work well with boats that are difficult to get on plane, underpowered or used in watersports where top-end speed is not critical. When the number of blades are changed, diameter and pitch may require a minimal adjustment to keep the RPMs in the proper range. Four blades in many cases will drop your rpm by 50 to 150 RPM with identical pitch. Three-blade props are generally best for recreational boats with three-, four- and six-cylinder outboards and sterndrives, giving good hole shot and top-end performance.

The blades on three-blade props fill up about 50 to 55 percent of the available area inside the circle formed by the prop’s diameter (referred to as the Diameter Area Ratio). Adding a fourth blade increases the DAR to between 60 and 65 percent, so you can expect more thrust to keep your boat planing at lower rpm, a potential boost in fuel economy, but also a reduction of 50 to 100 RPM at WOT.

Replacement Considerations

Selection Criteria - Gathering as much information as possible will allow you to make a better-informed decision when shopping for a replacement propeller. Useful information will include:

- Engine year, make, and model

- Current prop’s diameter and pitch

- Number of blades

- Right or left hand rotation (clockwise is right hand)

- Current RPM at WOT

If your current propeller’s performance is acceptable (WOT is within manufacturer’s guidelines) - Choose a replacement prop that is very similar to the diameter and pitch of your current boat prop. You might consider upgrading to a different material such as stainless steel or trying a 4-blade prop instead of a 3-blade.

If your current prop is unsatisfactory - What if your engine operates at the wrong RPM at WOT? Pitch and RPM have an inverse relationship; increasing pitch reduces RPM and reducing pitch increases RPM. A 1" change in pitch will usually result in a 200 RPM change in engine speed. Therefore, if your engine operates below the optimum proper RPM, you should consider a boat propeller with less pitch. If your engine over-revs, consider increasing the pitch.

Example: Your sterndrive tach limit (red line or RPM limit) is 4800. Your motor at WOT with full trim only turns 4300 RPM. Buy a prop with 2" less pitch to bring it up within 100 RPM of your tach limit. Your acceleration will improve, and your top end will stay the same or improve because your engine puts out more power closer to its rev limit.

You might also consider changing the propeller size to affect a specific performance attribute. A lower-pitch power prop makes it easier to pop skiers out of the water. Tournament bass boats may need more top end speed and should use a boat prop with a higher pitch. Houseboats and cruisers care more about efficiency at displacement speeds; therefore, they require a lower pitch to achieve low-end power and the largest diameter their lower unit can handle.

Modular Props (Exchangeable Hub System, XHS) - Modular boat propellers are becoming increasingly popular. In fact, many engine manufacturers are now selling modular boat props as original equipment. Modular hub systems consist of a hub that fits on to the splined shaft of the engine and the prop body which fits on to the hub. These systems offer two main advantages. First, in the event of a significant prop strike, the composite hub breaks away, which reduces the chance of damage to the engine, engine drive or propeller. Damaged hubs are easily user replaced and this lowers the replacement cost of the prop strike. Also, if the prop is bent but the hub is intact, replacing just the prop is also less expensive. Either way you stand to save $$$ if you have a problem.

How to Order A Modular Prop - When ordering a modular prop, you’ll need to order both a hub kit and boat prop housing. First find your engine in the charts or in the online selection tool and order the hub kit that matches your application. Then select a propeller body from the corresponding series that suits your boating style or is the closest replacement for your old prop.

Elevation - If you regularly run your boat at different altitudes, you know the importance of using boat props with a different pitch to match your engine performance. Reduced concentrations of oxygen at high altitudes cause engines to produce less power (about 20 percent less at 7000 RPM). Having two props pitched 2" apart lets you optimize the power of your engine. Modular props allow you to save money on that second boat propeller.

Be Prepared - Always have an extra propeller on board with tools to change it. If you have a prop strike or spin out a hub you will only be delayed a few minutes and not miss out on all the fun.

Additional Info

Propeller Terms - “Prop Talk”

Propeller size is expressed with two numbers, diameter and pitch, with diameter always stated first. Diameter is two times the distance from the center of the hub to the tip of any blade. Smaller prop diameters generally go with smaller engines, or with fast high performing boats. Pitch is the theoretical forward distance, in inches, that a propeller travels during one revolution. There is always some “slip” between the propeller and the water (generally 10 to 15 percent) so the actual distance traveled is somewhat less than the theoretical value. Think of pitch as speed, or as the gear selection on a car’s transmission. The prop size is often time stamped into the propeller. It can be found on the outer rim around the hub or on the cylindrical part of the prop body in between the blades. If the size itself is not stamped into the prop there should hopefully be a part number, either after market or OEM, that is stamped into the prop somewhere that we can try to cross reference to figure out the size.

Rake is the degree that the blades slant forward or backward in relation to the hub. Rake can affect how water flows through the propeller, which can make a difference regarding boat performance. Aft rake helps to lift the boat’s bow, decreasing the hull’s wetted surface area and improving top end planing speed. Today’s aggressively raked propellers may require that you add a high performance trim tab to your shopping list. The blade tips of these new propellers may strike the older style trim tabs on your engine.

Cupping of the trailing edge of the propeller blade is common on many propellers. A downward curve of the lip of the blade (like a plane’s wing with the “flaps” down) allows a better hole shot, less slippage and ventilation, and helps the propeller get a better bite on the water. A cupped prop may allow the engine to be trimmed with the prop closer to the surface and will also decrease RPM by 150 to 300.

Ventilation - This problem occurs when air from the surface or exhaust gas from the engine gets drawn into the prop’s blades. The boat’s speed drops, the engine over-revs and screams, and the prop sucks air. Ventilation results from excessively tight turns, a motor that is mounted too high on the transom, or an engine that is over trimmed. Ventilation can also occur from prop designs that are not matched to the application, poorly designed props, props with little or no cup, or props that are worn or have damaged edges or cup profiles.

Cavitation often confused with ventilation, cavitation results from water vaporizing or “boiling” due to the extreme lack of pressure on the back of the propeller blade. Many propellers partially cavitate during normal operation, but excessive cavitation may result in “cavitation burn”, metal erosion or pitting of the prop’s blade surface. Causes of cavitation include incorrect engine height (outboards), dings or sharp corners in the leading edge, poor polishing, too much cup or crummy blade design. Cavitation can also occur from thru-hulls, sensors, or other turbulence-producing protrusions under the boat forward of the prop.